Students, PFS Volunteers and TechnoServe Staff Help Design New Cooling Equipment Solution for Ethiopia

Located outside Addis Ababa, dairy farmers start their day by filling large containers with fresh milk before transporting it to a local processing facility. By milking cows early in the morning, farmers can ensure their product is as fresh as possible before it gets processed into yogurt or cheese. For the farmers located farther away milk pick-ups and deliveries are less frequent, leaving the milk to sit at warmer temperatures longer, creating spoilage and quality issues. To address this problem, Partners in Food Solutions, TechnoServe and USAID partnered with University of St. Thomas engineering students to design an off-grid cooling system that would keep milk at an optimal temperature and extend its quality.

Erika Thiem, supply chain director for the dairy platform at General Mills, helped with the project. After coming off a global work assignment with Häagen-Dazs that took Erika to different markets around the world, she realized how much she missed learning about other cultures and making global connections. “This project intersected my experience working with dairy, global regulations, and understanding the realities of dairy farming,” said Erika. “For small dairy farmers in Ethiopia, milk has a tremendous value. By reducing spoilage and extending the milk’s quality, farmers can increase their earnings. In this case, farmers could almost double their returns.”

Designing a cooling system for remote dairy farmers comes with unique challenges. Simon Hailu, a food processing specialist at TechnoServe Ethiopia, helped facilitate the project from the field. He said, “The system needed to use a dependable and inexpensive energy source since power supplies are unreliable in the area. Additionally, the solution needed to be easy to clean and disinfect, and be affordable to develop in Ethiopia.”

Throughout the 2019-2020 school year, students worked together to come up with innovative solutions that could solve the dairy farmers’ problem. From insulated containers to a portable ice maker to solar and diesel-generated power systems, the team explored various approaches that challenged their assumptions and widened their perspectives. “Being a part of these kinds of projects presents some of the greatest engineering challenges,” said University of St. Thomas Professor Greg Mowry. “This project challenged students because it tested their capabilities and out- of-the-box thinking when they didn’t have access to all of our systems like reliable electricity. I think this project changed us for the better, just as much as the project helped others and that is perhaps the most significant aspect of all.”

Due to COVID-19, the students involved in this project were unable to build a prototype of their off-grid cooling system. They did, however, finish the design for an insulated stainless steel container with an ice core that keeps milk cool for up to eight hours and connects to an off-grid energy source like a solar system. The team recommended having farmers split the cost of sourcing an ice machine to make it more affordable. PFS partner TechnoServe is currently exploring ways to build a prototype of the machine to show its benefits to local farmers. “If the recommended system works fine, we can demonstrate it to farmers and micro-finance the project through institutions and other stakeholders,” said Simon. “We’re closer than ever to helping remote dairy farmers in the region improve their milk quality and increase their access to markets through this innovative solution.”

Cracking the Code to ISO 22000

Pristine Foods Limited, an egg processing company in Uganda that produces products for vulnerable groups such as children and the elderly, wanted to improve their safety measures by implementing a more robust quality management system. Advancing their food safety and quality programs would allow them to expand to new markets including supplying to international organizations that help combat nutritional challenges throughout Africa. Furthermore, obtaining an ISO 22000 Certification would also assure customers that their products are processed at the highest standards, increasing their confidence.

To help advance their quality management system, General Mills Regional Auditor for Europe/Australia Alice Millat offered to lend her expertise. “At General Mills I conduct audits at our suppliers’ facilities and act as a link between the suppliers and General Mills in the case of an issue or question. I enjoy working in quality control and love sharing my experience so volunteering with PFS was just too good of an opportunity to pass up,” said Alice. “During the past several months we’ve reviewed their ISO 22000 manual and their hazard analysis and control documents. Now, we are focused on helping them address some production challenges – especially storage issues,” she continued.

Despite the fact that this project was kicked off at the start of the COVID-19 pandemic, the volunteers have made great progress in helping the client prepare for an ISO 22000 Certification. “We’ve benefited greatly from PFS’ rich network of extremely rare world-class experts in food processing,” said Joel Guma, managing director of Pristine Foods Ltd. “The experts and support team at PFS who we’ve been working with have been highly knowledgeable, professional and always willing to assist. This tremendous help has certainly put us on a more confident path to obtaining an ISO 22000 Certification.”

Deepening Global Perspectives Through Mentorship

Johnson Kiragu, regional program director - East Africa at Partners in Food Solutions and Sarah Moberg, director of ITQ integrated operations at General Mills, joined the PFS mentoring program in November 2019 with hopes of developing a deeper global understanding, learning some new skills and fostering a new connection. What they didn’t anticipate was having to navigate a pandemic that spanned continents and impacted them both professionally and personally.

Luckily, Johnson and Sarah were able to use each other as a resource and sounding board in addressing COVID-19 related challenges they’ve encountered. “Earlier this year when COVID 19 first hit Kenya, I got a lot of helpful information and tools from Sarah that I shared with our clients to help them improve their safety and the safety of their staff,” said Johnson “Additionally, Sarah has helped me develop some best practices in leadership so I can become better at what I do, and be a greater resource for my clients during these unprecedented times.” Similarly, Sarah said that through her conversations with Johnson she has been able to expand her perspective. “I love that mentorship is a two-way relationship,” she said. “Learning flows in both directions and I’ve gained a trusted advisor in Johnson. That relationship will remain past the end of the mentorship program.”

Want to join the PFS mentorship program? We're looking for interested canidates who would like to mentor a PFS stakeholder and help guide them, while building skills in virtual coaching, entrepreneurial mindset, and cross-cultural competencies. Spend ~1-3 hours per month for one year serving as a PFS mentor. Contact [email protected] for more information.

Second Annual PFS Founders Service Award Winners Announced

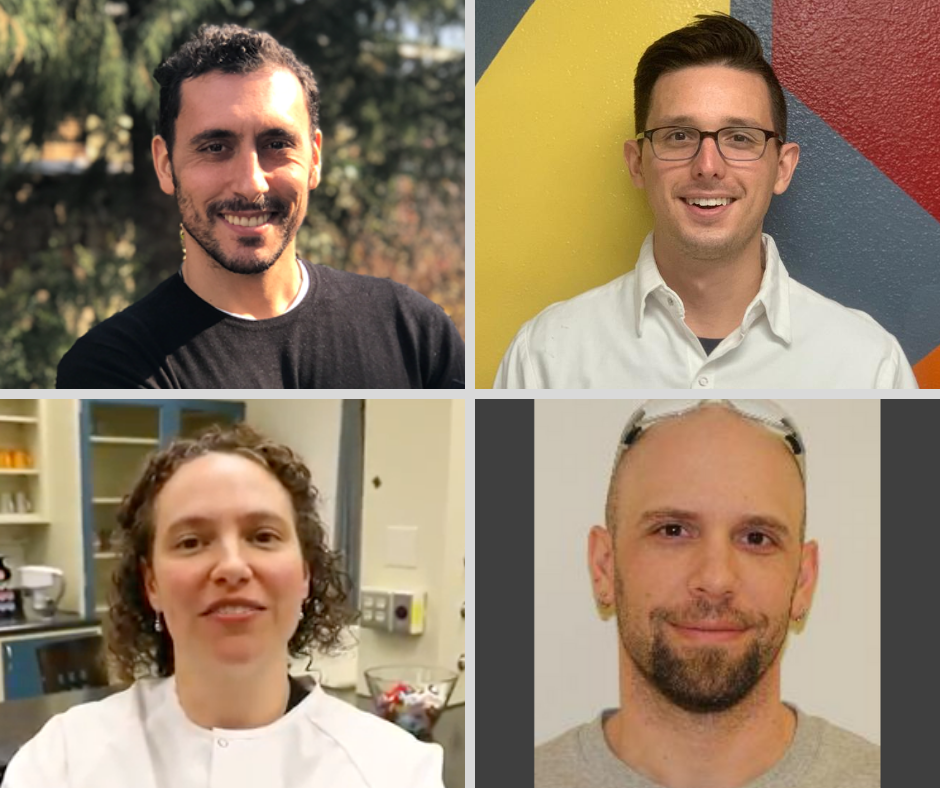

We are proud to announce this year's winners of the second annual PFS Founders Service Awards. These two awards, named after PFS founders, honor our volunteers who most display enthusiasm, drive for results, creative problem solving, tenacity and grit, wisdom, and humility. Please join us in congratulating:

John Mendesh Award

Mike Marshak, Business Technical Manager with Medallion Labs & General Mills

"Mike has been a tireless volunteer for PFS from its inception. His knowledge of food quality and safety and lab practices has helped PFS clients achieve numerous project milestones and completions. His willingness to help us out at any time, any day has made him an invaluable resource to PFS and our clients."

Jordana Swank, Director of Technology Development and Futures with The Hershey Company

"Jordana has been an amazing client lead. I admire how well she manages three different project teams. She is very committed to the projects and displays so much enthusiasm and clear thinking."

"Jordana has eagerly shared her technical and project management skills with several PFS clients over the years; she is always eager to join another project or role when the previous one wraps up."

Peter Erickson Award

Curtis Rainey, Assistant Quality Manager with Ardent Mills

"Curtis epitomizes dedication. He is currently supporting the Laboratory Analysis Project with Premium Foods in Ghana. He has displayed tenacity and humility to a large extent. He is punctual, responsive, and constantly joins project meetings; sometimes being the only volunteer on such calls. Curtis goes above and beyond to provide useful materials to the client."

Caio Malufe, Senior Manager in Corporate Development with Cargill

"In less than one year, Caio has volunteered to support three projects across two clients and is also a mentor to a TechnoServe employee in the early phase of their career. His calm demeanor and kindness are an ever-present complement to his business knowledge, and he makes himself available to talk with other volunteers outside of regularly scheduled team calls."

"Caio presents his expertise to clients and volunteer teams as his “experience” and what he has “seen” in the past, conveying his humility and approachability, and helping clients and teams feel comfortable working with him."

Erika Smith Joins Partners in Food Solutions as Senior Director of Client and Technical Services

With a lifelong passion for international nutrition and more than two decades of experience in the food technology space, Erika joins the PFS leadership team as the Senior Director of Client and Technical Services. “I am extremely motivated to be a part of an organization that is directly focused on the goal of strengthening food security, improving nutrition, and increasing economic development in Africa by leveraging food science, and other disciplines, to better the food value chain,” she said. However, this is not Erika’s first time being involved with our organization. She first joined PFS as one of our earliest volunteers in 2009. Back then, she led various projects for clients in Kenya and Cote d’Ivoire so she already knows a lot about how PFS works.

In her most recent role at General Mills, Erika led an international team as the Technology and Process Applications Director for the Global Dairy Business Unit in Vienne, France. She was responsible for technical strategy development and execution for General Mills’ global yogurt and ice cream brands. Her vast technical experience in the food industry makes her a valuable addition to our team and resource for our clients.

When Erika is not learning about the latest food technology trends, you can find her biking, hiking, golfing, and, most of all, traveling internationally with her husband, Mike. Some of her favorite travel experiences include bungee jumping in New Zealand, making spring rolls in Vietnam and hut-to-hut hiking in the Italian Dolomites.