In the world of food production, turning surplus ingredients into new, delicious products is a challenge that Co-op Ca Coprodigo,(“Coprodigo”) has enthusiastically embraced. The company, based in Côte d’Ivoire currently makes a diverse range of cashew-based products, including flavored cashews such as pepper, salt, and chocolate-coated, as well as creamy cashew butter.

They reached out to PFS for insight on how to transform surplus crushed cashews from their production process into innovative, tasty snacks. PFS connected them with Samantha Klein-Vidal, a research and quality technician at Ardent Mills.

Samantha and her co-volunteer from Cargill brainstormed and shared an impressive array of 21 recipes. From meringue toffees to cashew nut brittles, their brainstorming sessions produced culinary delights. From the numerous recipes, the Coprodigo team selected four recipes that stood out: a sugar and honey bar, chocolate candy with cashew, cashew cookie, and cashew clusters.

Coprodigo was very responsive and rapidly went into the testing phase for their upcoming star, Cashew Clusters. This exciting new product is a testament to the power of collaborative brainstorming and innovation. From discussions on the project call, the company has also explored additional avenues of processing cashew, such as cashew nut oil, roasted and unroasted cashew flour (potentially for mixing with baby food), cashew nut brittles, biscuits and coated cashew snacks.

Anne Tolou, marketing manager at Coprodigo, expressed her gratitude for the creative recommendations provided by Samantha and the volunteer team, emphasizing the company's commitment to staying fresh and expanding in the market. "These recipes will help us get there," she said with optimism.

Coprodigo's mission to add value to their surplus crushed cashews is an inspiring example of sustainability and innovation in the food industry. Samantha looks forward to the success of Coprodigo’s introduction of these new creations to new markets.

Fortifying foods that are already commonly consumed is of the most effective ways of tackling the micronutrient deficiencies that affect millions of people on the African continent.

PFS is grateful to four of our Africa-based volunteers from Buhler AG and dsm-firmenich who provided fortification training to members of the Ethiopian Millers Association and Edible Oil Association to support them to meet the National Fortification Standard. This was done in collaboration with the Ethiopia Food and Drug Authority and Standards Agency.

Over the course of three(3) days, Oreofe Odunsi, Rishan Elmneh and Kidist Tadesse, of dsm-firmenich and Biniam Tiezazu, from Buhler AG trained 32 millers and 29 edible oil companies on topics including microdoser installation and calibration, formulation and ratio adjustment of micronutrients to flour/oil and quality control testing and methodologies.

“Eshandy” is the trendiest beverage in Uganda! It’s a refreshing juice made from ripened bananas with no artificial sugars, flavor or color added. It is produced by Forest Fruit Foods (FFF) Ltd, an agro-processing company established in 2003.

Uganda is a leading grower of bananas in Africa. However, most of the produce is either exported or consumed in its natural state. Forest Fruit Foods is one of the few players that processes bananas on a commercial scale, with operations along the entire value chain. They do this because effective commercialization requires greater control on the value chain activities, as banana juice is a highly perishable product.

“Eshandy” is made from a variety of bananas that are native to regions in Uganda and Tanzania. Because of that there are no existing global resources or technical support available for processing these varieties. In addition, when packaged the banana juice does not have a uniform color, with bottles from even the same batch having different shades, which is quite undesirable for consumers. This is why FFF reached out to PFS to learn how they could stabilize their product.

With a background in microbiology and more than two decades of experience in food and beverage manufacturing, J.M Smuckers’ Sarah Mothershead was a perfect fit to help Forest Fruit Foods. Sarah had a number of hypotheses as to what caused the browning but she needed to prove them before she could propose solutions.

“The team, which included talented individuals from Forest Fruit Food Ltd., Partners in Food Solutions, and other volunteer members, was able to work together to understand the banana juice manufacturing and bottling process to develop test plans aimed at reducing the browning that was occurring in the shelf stable banana juice product over the shelf life in a warm environment. We were able to show that using antioxidants at differing points and in varying concentrations within the process serves to effectively minimize browning reactions. We were also able to provide support for the ideas of the FFF interns for further testing protocols and to bolster the food safety attributes of the product.”

Kano Kekurutso of Forest Fruit Foods, said “The team has been excellent with their commitment and level of organization, follow ups and practicality. They have been very realistic and accommodating.”Kano considers that the partnership with PFS is very instrumental, not only with the technical issues, but also the commercial aspects.“Through this project, we have more systematic and clearer technical controls and protocols. What some may consider a ‘small’ intervention will lead to huge results for Forest Fruit Foods. Resolving this browning will increase the shelf life of our product which will in turn increase the volumes of the bananas we purchase from farmers, and will lead to market expansion. We look forward to taking these trials from the lab to commercialization.”

Living in Zambia as a child, Kenzie Caron had the unique perspective of seeing Partners in Food Solutions (PFS) grow from an idea to the unique and dynamic organization it has now become in the fight against food insecurity. Yes, Kenzie’s father is PFS Co-Founder Jeff Dykstra, who developed the idea for PFS 15 years ago with General Mills. It’s not at all surprising that Kenzie is now a General Mills employee and a PFS volunteer. Her first project supported Cado Industries, a fruit and vegetable processing company in Ethiopia, to develop a marketing strategy for their portfolio of products. Cado Industries was founded in 2017 by Birhane Gebiresilassie, to mainly produce jams from locally grown fruits such as strawberries, mangoes, and papayas. Birhane was interested in diversifying Cado’s product portfolio to include other products such as fruit juices and syrups, candied and canned fruit, tomato paste and ketchup. He reached out to PFS requesting support for a marketing strategy not only for their existing fruit jam, but for their expanded product range.

As a senior brand experience planner at General Mills, Kenzie brings brands to life for consumers in her day to day work. She and a fellow volunteer from the J.M. Smucker Company worked to develop a holistic marketing playbook for Cado. They first started out with a SWOT (strengths, weaknesses, opportunities, threats) analysis, identifying the company’s areas of opportunity and weakness. They also evaluated the company’s target base as well as their competitors. All of this fed into the final strategic plan they laid out for Cado.

Kenzie said working on this project was very fulfilling. She not only had the chance to be connected to people from across the world, but also learned a lot, especially from the senior team member from Smucker with whom she collaborated. It was also an eye opening experience for her, deepening her sense of empathy for entrepreneurs like Birhane, who have overcome tremendous difficulties to succeed. “At the time of the project, Ethiopia was in the middle of a civil war and our client had to deal with the challenge of running a business in a war,” she said. “I learned a lot about compassion and empathy working with him, and my perspective was definitely broadened.”

After implementing the recommendations of the marketing strategy, CADO Industries’ sales tripled in comparison to the previous year. They also digitized their operations, developing an online presence which helped multiply their customer base. Birhane is grateful for the support offered to him. “Kenzie and her fellow volunteers were very helpful, humble and professional. They owned the project from end to end and have helped make my business a success!” For Kenzie, seeing Birhane’s responsiveness and acceptance, and implementation of their recommendations so quickly was very rewarding. It also showed her that as different as their worlds are, universal marketing truths still apply.

Kenzie’s advice to others interested in volunteering? “Just do it! As long as there are a couple of things in the description of the project that interest you and you have familiarity with, the rest will fall into place. You could also be partnered with others who may fill those gaps.”

Sweet Connections Cross the Globe

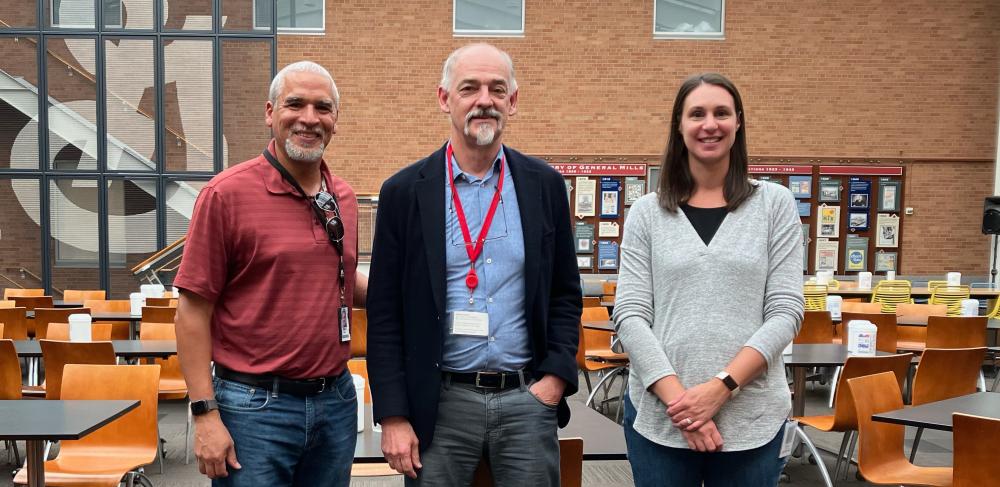

When Chris Majors, a director of quality and regulatory for General Mills, met Daniel Ball, managing director of the the Zambian client Forest Fruits, in Zambia during a PFS visit last October and they agreed to meet again. General Mills and Forest Fruits have one big thing in common - honey. So when Daniel was in Minnesota last month to visit with a honey broker he stopped by to see Chris at the General Mills research facility.

One of General Mills' biggest products - Honey Nut Cheerios - uses honey as a key ingredient and Forest Fruits is a processor of honey. A client of PFS since 2019, Forest Fruits is committed to improving rural livelihoods by developing business in rural areas of Zambia. It works with traditional beekeepers living in remote forests near the source of the Zambezi River in north western Zambia through an out-growers system that includes training and extension services. Their major product is honey, Zambezi Gold, that is distributed locally to all major retail supermarkets and grocery stores and is exported to the EU and southern Africa subregion.

Chris connected Daniel with Sarah Schramke, another R&D scientist, to see what possibilities there are. "He (Daniel) would be selling to a broker and then we would be buying from that broker," said Chris. "The brokers will blend honeys too so if we get the right blend with his honey in it, that's the idea." We'd be thrilled if the honey from one of our clients could be part of the great products of PFS' founding partner General Mills, bringing something very sweet full circle.

Photo left to right: Chris Majors, Daniel Ball, Sarah Schramke.